Explore the projects that define our craftsmanship — from structural steel to architectural glass and custom balustrades

At ProCraft, we don’t just install — we build. Every component we fabricate is processed through our in-house workshop, where skilled technicians operate state-of-the-art machinery designed for efficiency, precision, and quality control. This gives us complete oversight on every project and reduces lead times dramatically, ensuring that your design is brought to life exactly as intended.

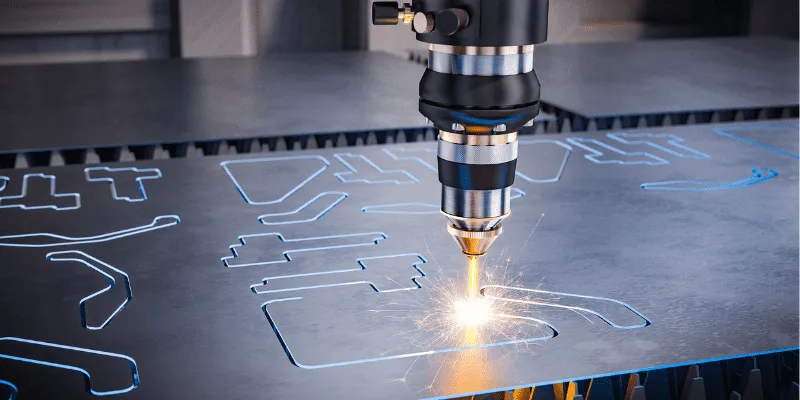

Our CNC Laser Cutter is the backbone of precision at ProCraft. Using high-powered lasers controlled by advanced software, we can create complex, detailed parts from metal sheets with incredible accuracy and minimal waste.

We use laser cutting for high-end architectural components that require a flawless finish and strict dimensional accuracy — particularly in glass support brackets, balustrade fittings, and aluminium features.

Our industrial-grade plasma cutter delivers powerful, efficient cutting of thick metals — ideal for the structural backbone of many of our projects. It’s perfect for heavier, load-bearing components where durability matters.

We rely on plasma cutting for structural staircases, load-bearing brackets, steel frameworks, and custom fabrication where strength and speed are essential.

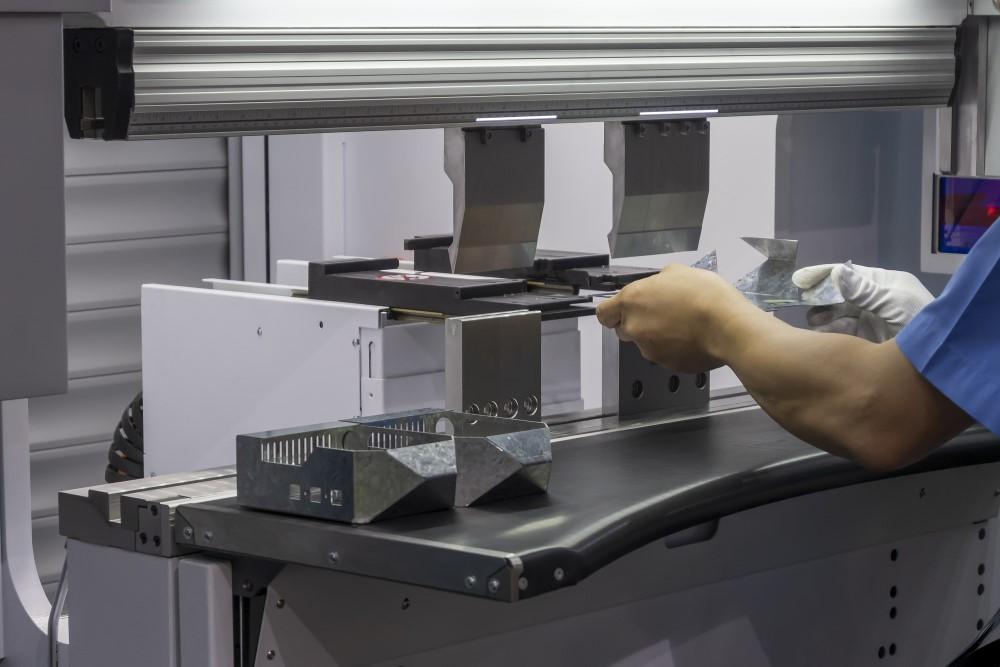

Our break press brings structure and shape to flat metal sheets, transforming them into ready-to-install parts with pinpoint bends and folds. Whether it’s creating curved handrails or detailed support components, this tool is essential to ProCraft’s versatility.

We use the break press to fabricate balustrade channels, stair brackets, aluminium fins, support plates, and decorative architectural cladding — all shaped with millimetre precision.

Whether it’s a bespoke staircase, a commercial fit-out, or structural steelwork — we’re here to help bring your vision to life with precision and craftsmanship. Get in touch with our team today to discuss your project.

Have a question or want to discuss a project? Reach out to Michael or John directly, or use the form below and we’ll get back to you as soon as possible.